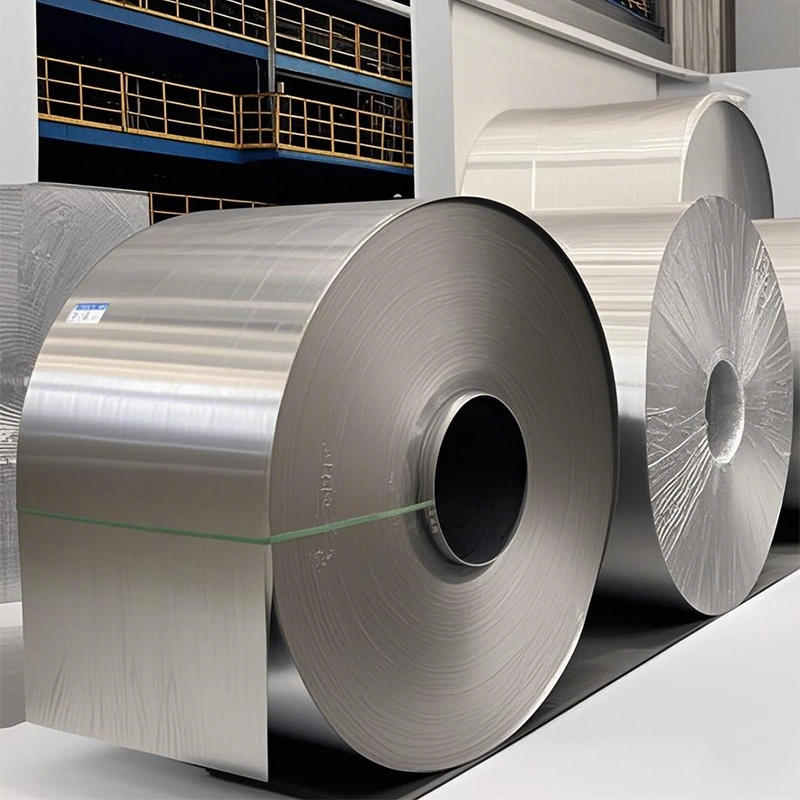

TMBP Tin Mill Black Plate Ideal for coatings and lamination

HJ GROUP's premium TMBP is a cold-rolled, uncoated steel sheet designed for precision applications. Manufactured using advanced low-carbon steel formulations and state-of-the-art annealing processes, it offers:

● Uniform Thickness: Tight tolerance control for consistent performance.

● Smooth Surface Finish: Ideal for coatings and lamination.

● Superior Mechanical Properties: High ductility and formability for complex shaping.

As the foundation for tinplate and TFS production, our TMBP sets the standard for reliability in packaging, automotive, and industrial sectors. Backed by HJ GROUP’s commitment to sustainability and innovation, it delivers unmatched value for demanding global supply chains.

Applications

Tinplate Manufacturing: As the core raw material for tinplate production, TMBP is critical in creating high-quality food and beverage cans, aerosol containers, and premium packaging solutions. Our advanced processing ensures superior formability and corrosion resistance for global brands.

Tin-Free Steel (TFS): Serving as the substrate for electrolytic chromium-coated steel (ECCS), TMBP enables lightweight, cost-effective packaging with excellent weldability and chemical resistance, ideal for beverage and food industries.

Crown & Bottle Caps: Engineered for precision, our TMBP guarantees hermetic seals in crown caps, ensuring product safety and shelf-life extension for carbonated beverages and spirits.

Automotive Components: Leveraging its high tensile strength and surface uniformity, TMBP is trusted in manufacturing structural parts, fuel tanks, and decorative trim for leading automotive manufacturers.

Household Appliances: Used in thin, durable components for refrigerators, washing machines, and small appliances, our TMBP balances strength, aesthetics, and manufacturability.

Product Specifications

|

Brand |

HJ GROUP,Since 1993 |

Temper |

T1-T5, DR7-DR9 |

|

Application |

Food or other industry cans |

Origin |

China |

|

Delivery Time |

20-40 days |

MOQ |

25MT |

|

Delivery Tolerance |

+/-5% |

HS code |

720918 |

|

Supply Capacity |

5000MT Monthly |

|

Packaging |

Standard seaworthy export packing or custom required |

Contact us today to discuss your TMBP requirements and experience HJ GROUP's commitment to quality, reliability, and global supply chain excellence.